Introduction

The Hjortspring boat has many peculiar characteristics that almost inevitably bring to mind its predecessors, who must have fostered them. Those of us who have the Hjortspring boat in our blood have therefore occasionally let our imaginations run wild in an attempt to recreate the predecessors of the Hjortspring boat.

The Hjortspring Boat dates from just after the Late Bronze Age, from a time when the last petroglyphs depicting boats were carved into rock faces in Bohus County in Sweden. Its profile depicts these youngest petroglyph boats. But how were boats in the Early Bronze Age built, at a time when tools did not have the superior cutting power of iron? Unfortunately, there are no archaeological finds of Bronze Age ocean-going boats to rely on. In an attempt to describe these, we must use methods other than archaeological methods to answer the question of Bronze Age boat construction. Here we will use the petroglyphs' statements together with a form of “backwards product development” from the construction of the Hjortspring boat.

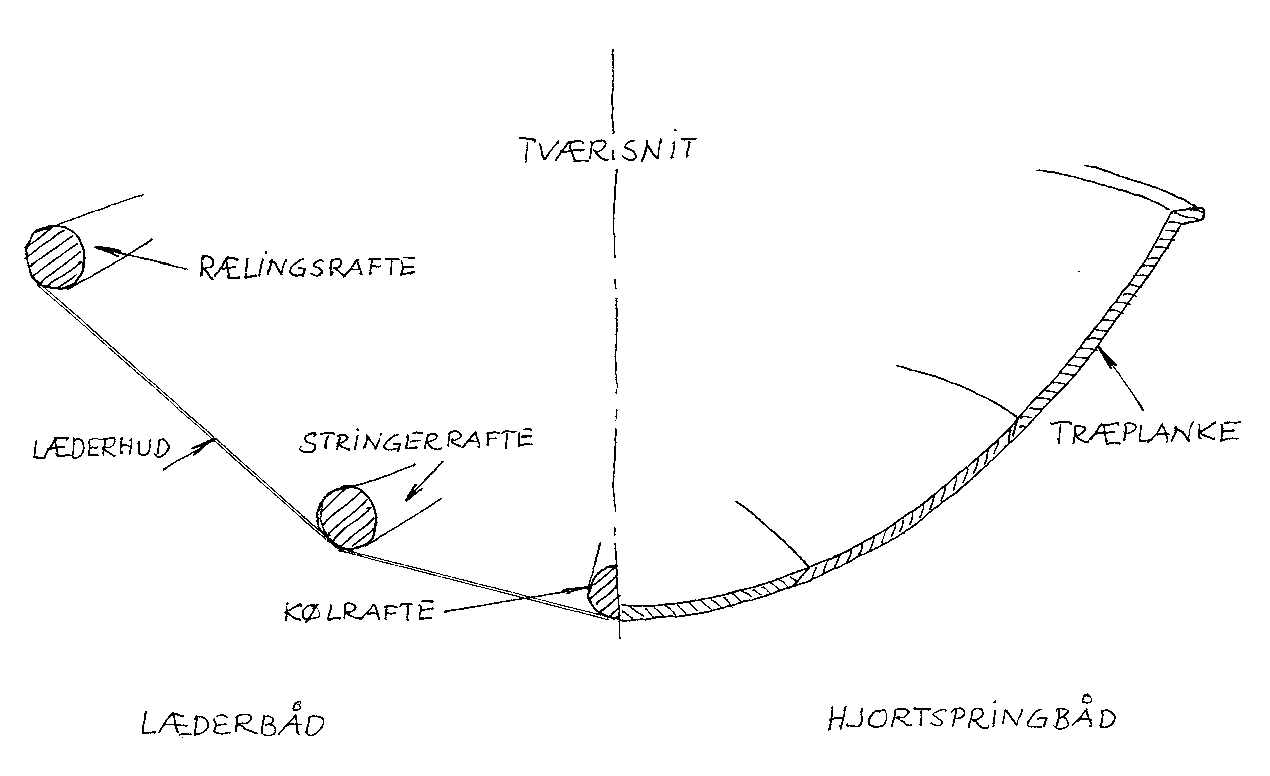

What the hand shapes is the trace of the spirit, we can thus rewrite the statement: ‘What the hand shaped was the trace of the spirit’. Our predecessors in 350 BC must have inherited some constructions and designs that formed the basis for their solutions. We have already seen that petroglyph boats back then, in the Early Bronze Age, had straight keel and railing lines, an impossibility to achieve in ocean-going wooden boats without unrealistically large logs. If we emphasise that Bronze Age societies were largely based on cattle breeding, we can hardly avoid wondering about the use of ox hide in tanned form, i.e. leather, for making ships.

If we assume that trade in the Bronze Age in Scandinavia relied more on sea transport than land transport with ox-drawn carts, the production of boats and ships must have been an important activity, just as the car industry is today. This leads us to the conclusion that the cost of production, i.e. the time it took to make a boat, was important.

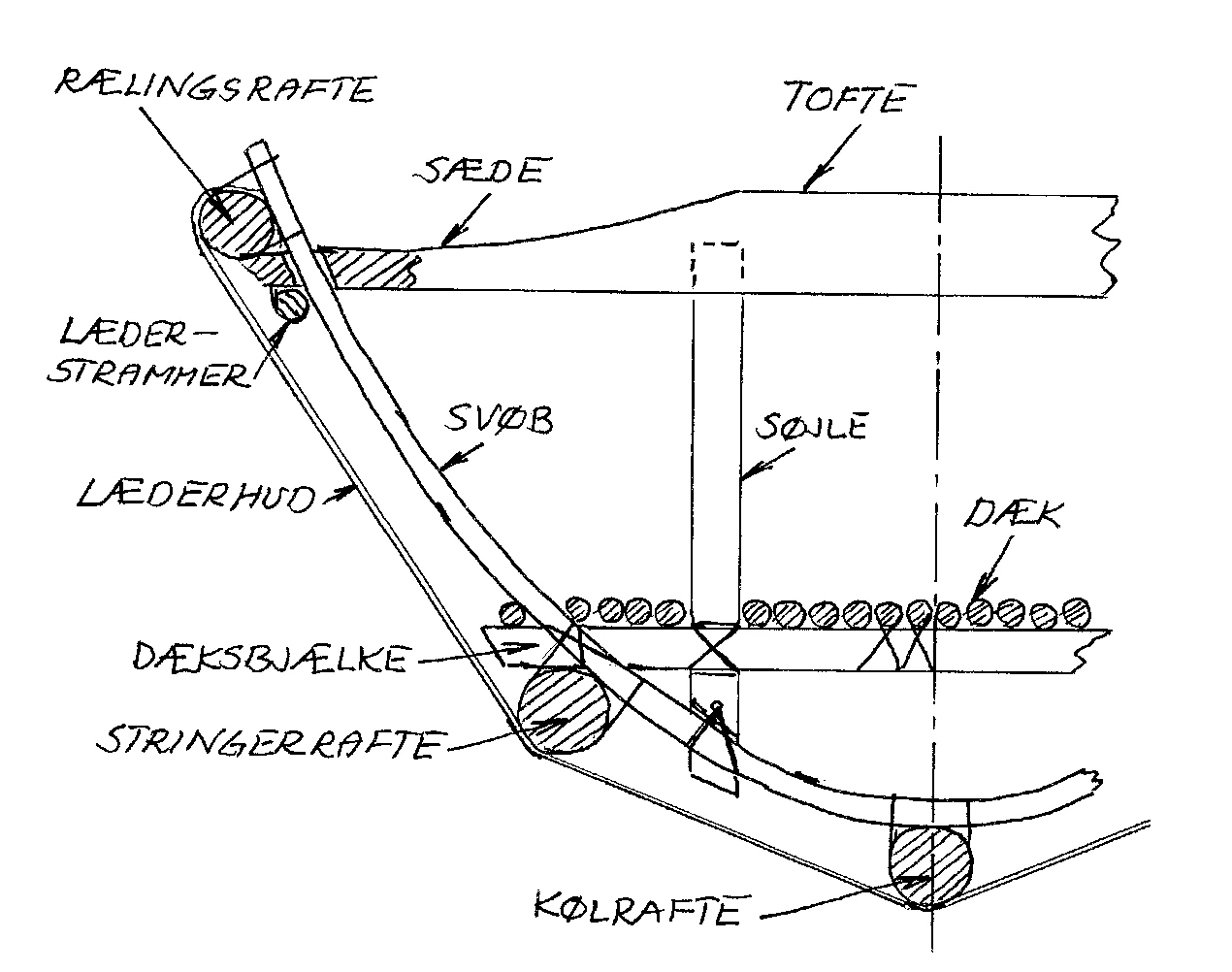

The main construction of the Hjortspring boat can be characterised as a longitudinal, stretched beam, a boat shell that is in principle self-supporting. The frame systems are of course used to maintain the shape of the shell, especially to counteract ‘pea pod’ movements. The webs themselves are far too weak to support the boat shell, but they transfer the external loads between the different parts of the shell with the help of the other elements of the frame systems, i.e. roofs, deck beams and columns. In addition, the frame elements transfer forces from the weight of the crew and cargo to the shell in balance with the buoyancy of the water.

The frame systems do little to counteract torsional moments from wave movements.

The Hjortspring boat is very elastic when it comes to torsion. This is typical of Scandinavian boat designs from the Iron Age to the Viking Age to the early Middle Ages.

A skin boat hypothesis

We have come to the conclusion that the boats or ships that transported large amounts of goods across the Scandinavian seas and along the coasts could have been made of leather-covered rafters.

Not that this is an innovation among hypotheses. Throughout the twentieth century, marine archaeological scientists have debated ‘wood or skin’ in the Bronze Age. However, we think that in addition to the straight railing and keel lines, the Hjortspring boat's frame systems have a construction that may point in the direction of a raft construction. The horns may also contain reminiscences of a raft boat where they were useful.

To test this hypothesis, we constructed a leather/raft boat the size of the Hjortspring boat.

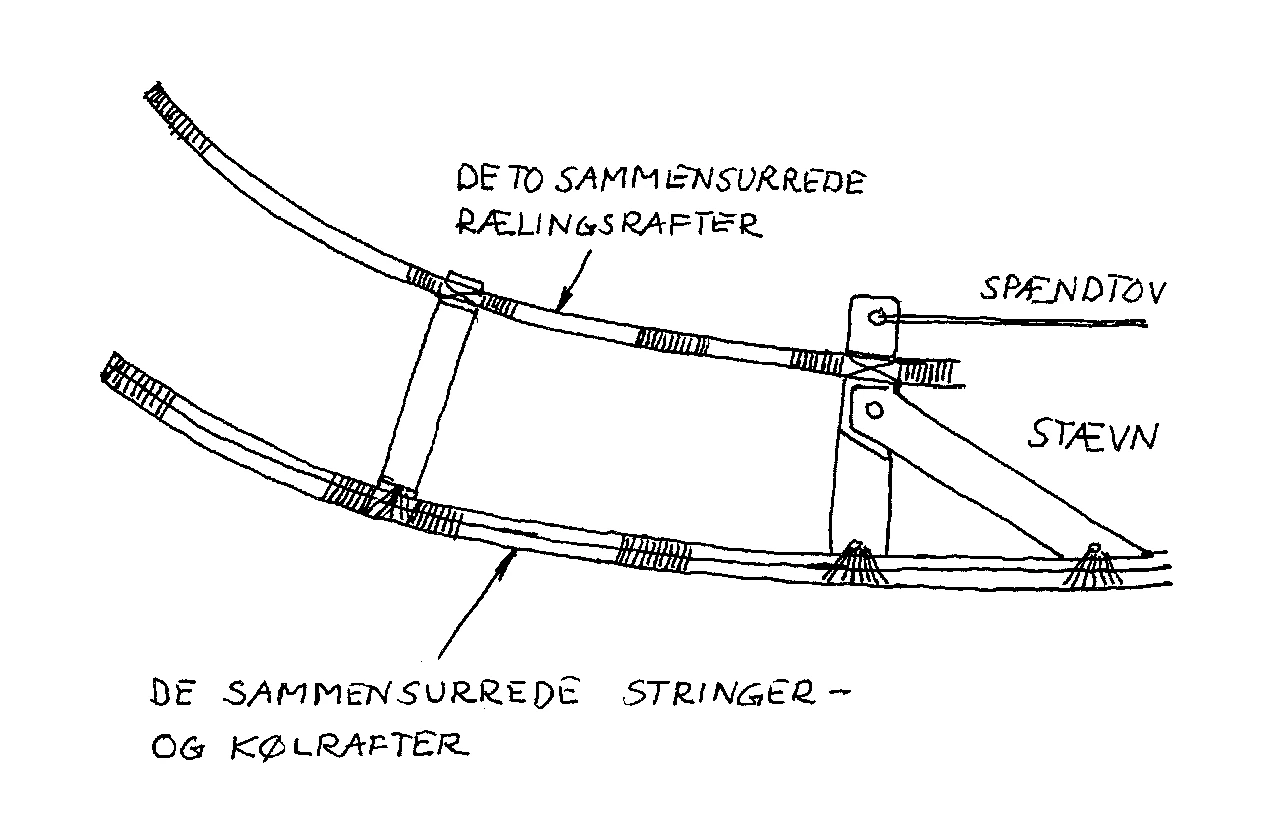

The longitudinal elements were chosen to be five debarked rafters, i.e. two railing rafters, two side or stringer rafters and one keel rafter.

The diameter of the rafters amidships (100 mm) was chosen on the basis that the torsional resistance of a boat cross-section corresponds to the corresponding resistance of the Hjortspring boat. A very simplified mathematical model has been used here, but it provides guidelines. It is expected that the raft diameter decreases by 5% per metre from the centre of the boat towards the ends of the boat.

The two rake rafters run together fore and aft and are lashed together over two metres, forming the rake horn. The function of this long lashing is to prevent longitudinal slipping and twisting between the two rafters, thereby preventing the boat from twisting. The same effect can be achieved by lashing the two stringer rafters together fore and aft, where they lash together with the keel rafter to form the keel horn.

A triangular construction at both ends of the boat forms the bows.

The frame systems mimic those of the Hjortspring boat, although they are somewhat less elegant and less weight-optimised to illustrate the inferior cutting tools that existed in the Bronze Age.

The skin of the boat itself is tanned cowhide with a thickness of 3-5 mm. It is essential that this leather membrane, when subjected to water pressure, does not bulge inwards so much that it touches the hull or frame parts. Calculations have been carried out on the bulging as a function of rafter spacing and water pressure based on permissible tensions of cowhide belts used as drive belts. These calculations show that the design is possible.

Physical model

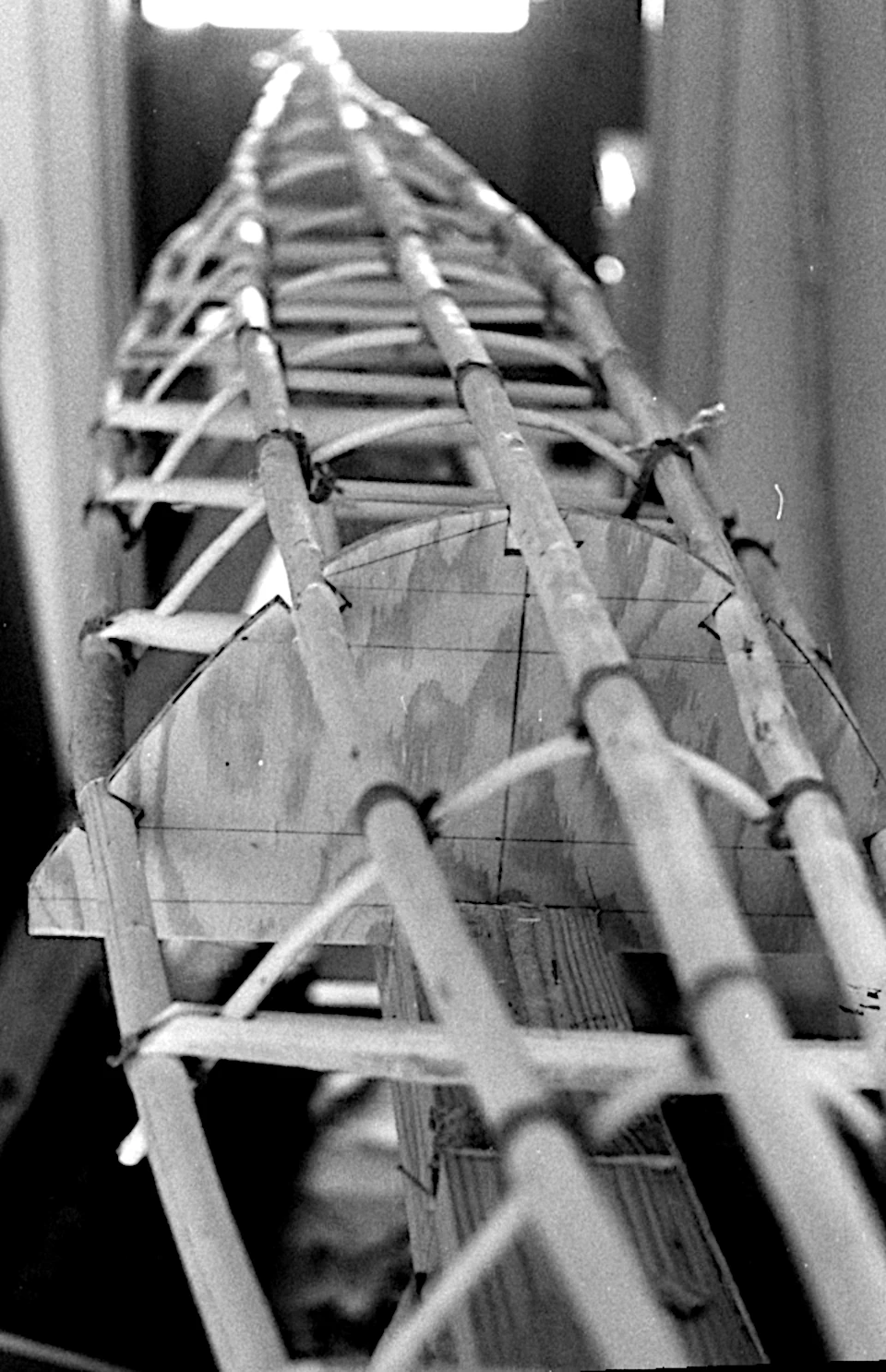

Based on the design, a physical model was made in 1:5 scale. Apart from the thickness of the hide, the model laws are linear, meaning that a 100 mm raft must have a diameter of one fifth, or 20 mm. The rafts were made from debarked hazel branches.

The skin was tanned water buffalo hide with a thickness of 1.5 mm. A series of cuts were made in plywood with notches in which the rafters were placed. By using fresh hazel branches that were forced into the notches after debarking and secured, the rafters retained their forced shape after they had completely dried out.

Each raft consisted of two trees lashed together amidships over a length of 20 cm (1 m).

At the centre, the rafters had a diameter of 20 mm. This diameter was reduced towards the ends, so that the rafters at the horns were only 14 mm in diameter.

When the fixed rafters were completely dry, the plywood profiles were replaced with wraps of 8 mm hazel branches, which had also been fixed in their arch from fresh to dry before installation. The wraps were lashed to the rafters after the ceiling had been installed on the frames.

Then the stems were made and mounted. Finally, the ends of the rafters were lashed together to form the horns. A skew in the boat's skeleton caused by twisting of the beam on which the profiles had been mounted could be partially eliminated by shifting the rafters longitudinally in relation to each other before lashing. However, the boat was not completely straight.

Next, the deck beams and columns were lashed to the rafters and webs, and finally the deck was lashed to the deck beams. For these lashings, 1 mm synthetic cord was used. The lashings that secured the sails to the rafters should probably have been embedded in the rafters to get a smooth surface of the leather where it passed through the lashings. A stretch rope had been placed between the two bows.

The leather skin was fitted from the stern forwards.

The seams were made with a double seam. Once the skin was roughly shaped, it was soaked in water, fixed aft and stretched along the boat. Next, it was fixed at the front in a very tight position. Finally, the leather skin, still soaked, was stretched crosswise over the railing, to which it was lashed.

The finished model weighed 5 kg, which means that a similar full-size boat would weigh 625 kg, or almost 25% more than Tilia. With the right thickness of leather skin, it is estimated that a ‘Hjortspring boat’ in leather/rafte technology would weigh the same as Tilia.

Dividing the production of a boat into the three elements: machining, moulding and assembly, we can compare the two technologies. There is a dramatic difference between the wooden boat and the leather boat.

Machining accounted for 85% of the work on the wooden boat compared to 10% for the skin boat, moulding accounted for 1% compared to 50% for the skin boat, while assembly for the wooden boat accounted for 14% of the work compared to 40% for the skin boat. In other words, a skin boat requires almost no machining. The tanning of the hides is not included here.

The production of the model did not provide any information on the relationship between the production time of a wooden boat and a skin boat.

No tests were carried out on the scale model. However, it seemed robust, even when twisted.

Conclusion

The completed construction of a ‘Hjortspring boat’ in raft/leather technology proves nothing. You could say that it concretises the hypotheses that postulate that such boats could have been used in the Early Bronze Age. A next step could be to build and sail such a boat, a step that, if successful, would give a higher degree of probability to the hypothesis.

Webmasters note

"5,000 years ago, a Scandinavian Stone Age people travelled in skin boats similar to those used by the Inuit further north. ..."

The above is a quote from an article in Videnskab.dk:

New study sparks old debate: Which boats did the first Scandinavians use?

This shows that K.V. Valbjørn is not alone in this thought, there are, at least some, researchers who agree.